"SteyrTMP" (SteyrTMP)

"SteyrTMP" (SteyrTMP)

01/18/2014 at 13:30 • Filed to: None

1

1

20

20

"SteyrTMP" (SteyrTMP)

"SteyrTMP" (SteyrTMP)

01/18/2014 at 13:30 • Filed to: None |  1 1

|  20 20 |

Edit: Reposted for the normal, 9-to-5 crew.

Grr. Someone had a really good term for Opponauts... other than Opponauts, and I've forgotten it. Oh well.

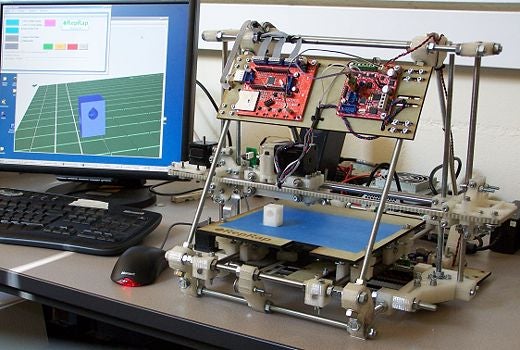

Ever since I started working on the Seven GTR, I've been very interested in CNC. My ultimate goal is a 6'x12' gantry CNC router, so as to be able to shape car bodies out of large foam blocks. Particularly, the 962, and the 911 GT1. I have contact with someone that has tube-frame blueprints for the 962, rather than the aluminum-tubbed original chassis. However, there is no affordable source of 962 body parts.

Oh well. It costs between $1500-3000 to make, and that's down the road. I need a little more experience (although, I don't think it's going to take that much more than what I've been doing now, if not less), and a much larger garage to put it in.

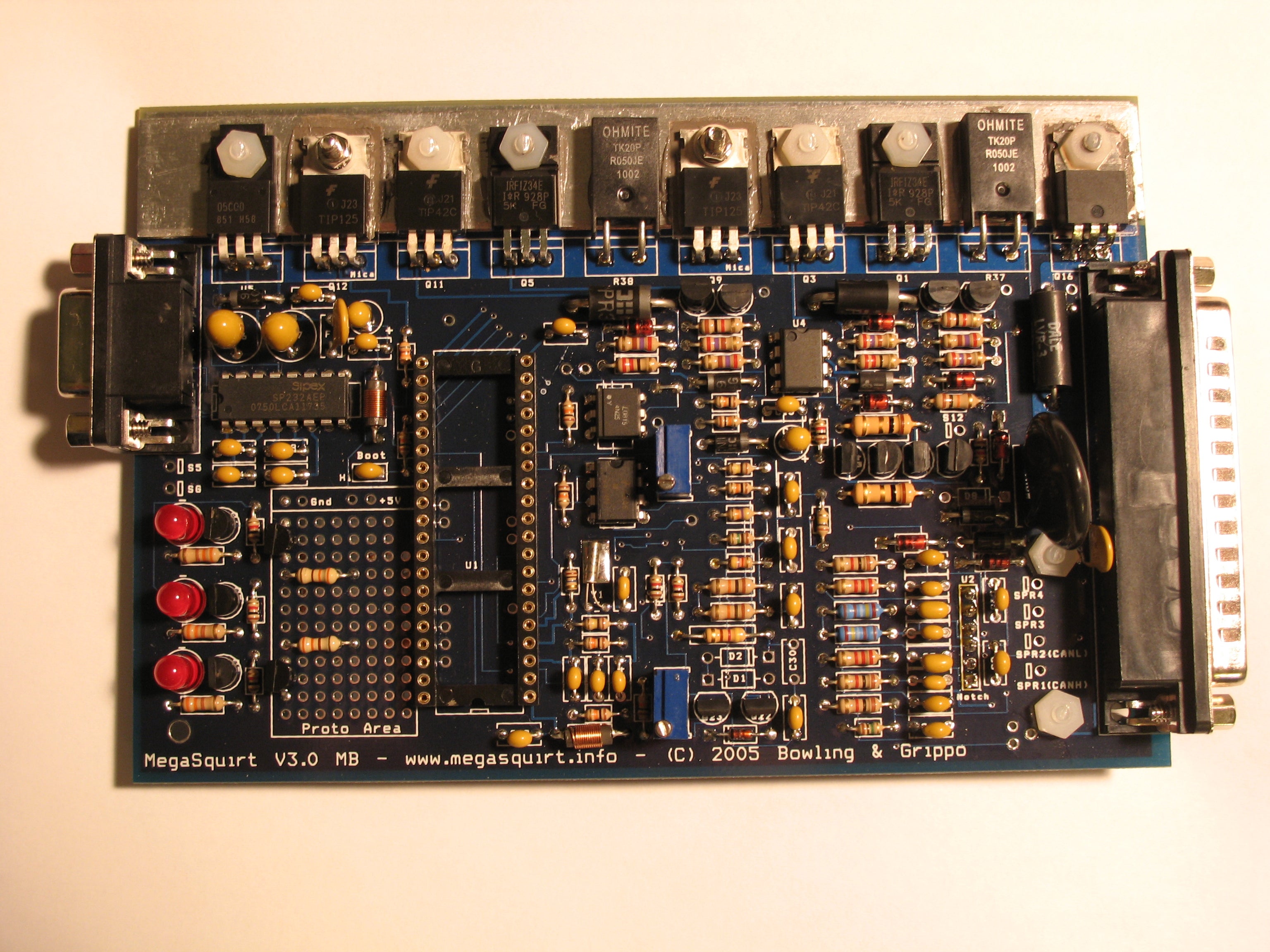

For now, I am looking into building a RepRap. I want to start with a standard model, and then from there go to a 2x or larger scale version. I'd like to have a 2'x2'x2' build area, if not larger, eventually. However, from experience, the farther you try to go off the beaten path, the harder it is. It's always better to start with the proven, and go from there. It is going to be a lot like building the Seven, and the MegaSquirt III. All three are open-sourced, and the only major downfall of open-sourced projects is the lack of complete instructions and constant evolution. Like the Megasquirt—there are so many different instructions for a Miata, but you can't use a little here, a little there... you need to go from start to finish on one variant, otherwise you end up with a total headache. I know the RepRap will be the same. There are numerous variants, and I'd have to work very hard to find one complete build plan start-to-finish.

Anyone think it would be a good idea?

The only problem: Money. It costs between 300-400 to build one. Right now, where I'm working, I am making less than I did before I went back to school. I'm doing 50+ hours a week, which makes up for the money difference, but it takes up all of my time, and I'm still struggling to make ends meet. I have no extra cash for hobbies/interests.

So I thought of perhaps making a Kickstart for $500-600 to make a RepRap. That would leave enough extra for expendables and any spare parts needed. I figure $10-$50 donors would get build information and updates (although that'd be a hard sell—I assure you the build would be here, as well as two or three other forums), $50 or $75+ donors would receive a copy of the reproduced RepRap parts (all the plastic connector parts, gears, etc are reproduced from another RepRap.

I've seen people doing Kickstarts for less, (the Lambo guy comes to mind), and some companies use it as well. My only concern is that with two children, it will take a while to complete. I wouldn't be able to guarantee a fixed time frame, although it would definitely get completed. I am very interested in rapid prototyping, and 3D printing is definitely part of it, as well as part of the future. The experience of making and using my own would benefit in numerous ways.

Anyone think it would be a good idea? Has anyone made a Kickstart before?

ToyDeathbot

> SteyrTMP

ToyDeathbot

> SteyrTMP

01/18/2014 at 03:49 |

|

Make a RepRap only if you have the time and bother to be dedicated to keep on improving and tweaking the thing. I've had one for two years, and I haven't even begun to print anything decent yet :(

Time really has to be on your side to make a good RepRap. If you don't, just use Shapeways.

SteyrTMP

> ToyDeathbot

SteyrTMP

> ToyDeathbot

01/18/2014 at 05:03 |

|

While I don't have time, I have my dad... who happens to be a very good programmer, as well as pretty damn good at electronics on the side.

BTW, from the picture, one would think you just stick 'em in and solder... not quite... the variants of the MSIII are almost infinite. But he got it working on the first try. I partially wanted to do the MS myself, but I figured, while I can probably learn to solder decently—it's like downsized TIG—that was probably not the place to start.

SteyrTMP

> ToyDeathbot

SteyrTMP

> ToyDeathbot

01/18/2014 at 05:03 |

|

Have you printed anything at all? What's your holdup?

davedave1111

> SteyrTMP

davedave1111

> SteyrTMP

01/18/2014 at 06:41 |

|

If you wait a year or three you'll be able to buy a working 3d printer from a big box store for less, instead of wasting your money on repcrap that will never work.

I have no big problem with open source in general, but one of the things it tends to encourage is for people to focus on the sexy, exciting, big-picture stuff and ignore the truly vital but less-feted work of fixing bugs and making minor tweaks. Which is why Reprap not only doesn't work, but I'll practically guarantee that it'll never work.

Jayhawk Jake

> SteyrTMP

Jayhawk Jake

> SteyrTMP

01/18/2014 at 09:12 |

|

I don't have any input, but is the term you're thinking of "Oppoite"?

SteyrTMP

> Jayhawk Jake

SteyrTMP

> Jayhawk Jake

01/18/2014 at 12:42 |

|

No, it was an alteration of a traditional word.

SteyrTMP

> davedave1111

SteyrTMP

> davedave1111

01/18/2014 at 13:30 |

|

I have to say, it seems as if you've contradicted yourself. If I were to buy one from, say, Walmart, in the theoretical future, I would have a lot less bug-fixing and tweaking, rather than if I had made one myself. Going by that theory, then the MSIII wouldn't work, and I should have bought an AEM or MoTec system instead.

If they never work, how do all the kits get out there? They're being reproduced by other RepRaps....

davedave1111

> SteyrTMP

davedave1111

> SteyrTMP

01/18/2014 at 17:22 |

|

Last time I checked, there are basically no Repraps out there. To get them to work, they have to be customized/tweaked/fiddled with. Which is the point I was trying to make, by the way: the big picture reprap concept was sexy, attractive, but smoothing out the small imperfections so people can actually build them - no-one's interested.

"I have to say, it seems as if you've contradicted yourself. If I were to buy one from, say, Walmart, in the theoretical future, I would have a lot less bug-fixing and tweaking, rather than if I had made one myself. Going by that theory, then the MSIII wouldn't work, and I should have bought an AEM or MoTec system instead."

I have no idea what that was meant to say, sorry. What's the contradiction?

SteyrTMP

> davedave1111

SteyrTMP

> davedave1111

01/18/2014 at 18:35 |

|

Never mind... I read the statement differently than you meant. I still think it is feasible. The MS is the same way. It takes tweaking and experimenting, and only the hard core enthusiasts get them working. I'd rather take the chance. Once I've put money into something, I refuse to give up, even if it means more work than its worth.

Redbulldidlo

> SteyrTMP

Redbulldidlo

> SteyrTMP

01/18/2014 at 18:51 |

|

Don't make a kickstarter for this. Kickstarter is for starting companies and buisness ventures, not personal projects.

SteyrTMP

> Jayhawk Jake

SteyrTMP

> Jayhawk Jake

01/18/2014 at 22:45 |

|

Now I remember Oppostles. LMAO

SteyrTMP

> Redbulldidlo

SteyrTMP

> Redbulldidlo

01/18/2014 at 22:59 |

|

No offense, but you obviously haven't read my post, or the Kickstarter mission statement... It's art/research based, not business based. If I can figure out how to get one running, make parts for more, and explain a well-documented how-to, how is that not under their "What is Kickstarter" definition?

Redbulldidlo

> SteyrTMP

Redbulldidlo

> SteyrTMP

01/18/2014 at 23:03 |

|

Either way, people aren't going to just give you money to have a reprap, just because you want to make fun stuff.

http://yourkickstartersucks.tumblr.com/

These people are what you'll look like.

SteyrTMP

> Redbulldidlo

SteyrTMP

> Redbulldidlo

01/19/2014 at 02:21 |

|

The whole idea of Kickstarter is to fund a project. Donors would receive a RepRap plastics kit, along with detailed information on how to make one. I'm missing how this doesn't fit Kickstarter in your mind.

You sound like a troll.

ToyDeathbot

> SteyrTMP

ToyDeathbot

> SteyrTMP

01/19/2014 at 10:27 |

|

I've only been printing some calibration squares but some problems have already started to come out, such as problems with the hot end, unstable platform, worn out bushings and broken belt clamps. Currently it's all tweaking and frustration so I'm taking it slowly, otherwise I might end up going online and re-buying parts for everything - which isn't particularly nice for my wallet.

ToyDeathbot

> SteyrTMP

ToyDeathbot

> SteyrTMP

01/19/2014 at 10:31 |

|

Programming and soldering isn't particularly important unless you want to do everything yourself (it's hard enough as is) or you've made a new unconventional design that no one else has ever made. Otherwise, the current Arduino-based solutions are good enough as is (cheap, reliable, easy to tweak).

Redbulldidlo

> SteyrTMP

Redbulldidlo

> SteyrTMP

01/19/2014 at 10:37 |

|

Because the detailed information is already available, and you can already get the parts. You are not doing anything new whatsoever, that's how.

SteyrTMP

> ToyDeathbot

SteyrTMP

> ToyDeathbot

01/19/2014 at 14:02 |

|

Which hotend are you using? And if you are having things break, if it can be machined, let me know. I'm going to make my own hotend using the lathe and mill. I forget which model I was looking at, but I have it part-way done downstairs somewhere. I haven't had a chance to breathe lately, let alone get anything finished.

ToyDeathbot

> SteyrTMP

ToyDeathbot

> SteyrTMP

01/20/2014 at 07:32 |

|

I got it here: http://www.emakershop.com/browse/listing…

It's a pretty untested DIY-type build though, and I'm kinda regretting the choice now...I could have spent an extra few dollars and gotten a J-head instead.

I unfortunately don't have access to a workshop at all, so all my stuff has to be brought online.

SteyrTMP

> ToyDeathbot

SteyrTMP

> ToyDeathbot

01/20/2014 at 13:14 |

|

I started machining a J-head, if I remember correctly. If I ever get further,

I'll see if I can make an extra one for you.